Induction Case Hardening

Induction case hardening amplifies performance of parts by providing hybrid mechanical properties, hardness on wear surfaces, and ductility in the core to provide impact resistance. Induction heat treating targets and applies heat rapidly throughout the specified case hardened zone. This is ideal for parts that are highly stressed in operation and require a combination of mechanical properties. We are able to customize our machines, coils, and processes to fit your needs. Once parameters are set, we can assure consistency between parts.

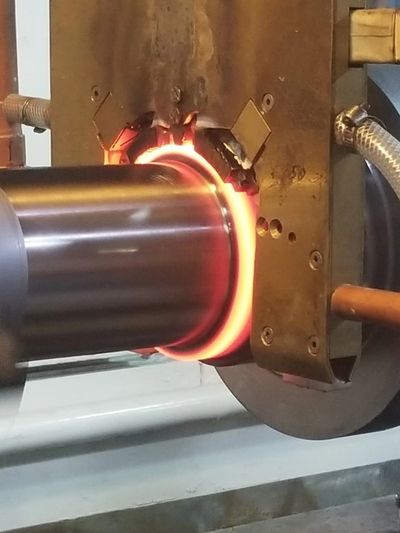

Large crankshaft in processes of being induction hardened.

Capabilities

With use of some of the most versatile equipment in the industry, our metallurgist and engineering staff provide the technical expertise to develop tooling and processes for your induction heat treat application. Our typical applications of induction hardening include crankshafts, cam lobes, gears, shafts, axles, and spindles. We are also experienced in machining parts; having developed processes using techniques such as turning, milling, and drilling.

Power cabinet of an induction hardening unit.

Quality

CQI-9 & ISO 9001:2015 Certified

Learman Electronic Tool is an ISO 9001: 2015 Certified Heat Treating company. Our quality department is key in providing the highest level of service to our customers. Our quality and performance is reflected by our major OEMs and our supplier approvals. We believe that innovation is vital to our efforts to remain an industry leader. With that goal, we have continually invested in new technologies and Heat Treating equipment to ensure that we are at the cutting edge of every stage of our process capabilities. These systems are continual reviewed to identify inefficacy. We are committed to providing products and services that meet or exceed the requirements and expectation of our customers.

Why Our Customers Continually Partner With Learman

Our customers must be competitive while maintaining the highest level of quality. For that reason, all parts are processed, monitored, controlled, and inspected by highly trained personnel using modern state of the art equipment. Because we are committed to the highest level of service, we continually invest in new equipment and technologies. This makes Learman a first choice for many companies with Heat Treating needs. We have established rigorous quality standards and regularly evaluate and improve all aspects of our quality system and production processes to ensure we are meeting our commitments.

Inspection

Inspection

- ROCKWELL HARDNESS TESTING

- MICROHARDNESS TESTING

- CASE DEPTH ANALYSIS

- MAGNETIC PARTICLE INSPECTION

Induction Hardening of 6.4L Powerstroke

Contact Us

Contact us today.

Hours

Open today | 07:00 am – 04:00 pm |